Watch the video

TERMINTER

Technological and Environmental Innovation

Our Story

With such a wealth of experience, the company has undoubtedly acquired a prominent place in the market, distinguishing itself through quality and technological innovation of products.

We have often used proven technologies, especially foreign ones, in the design and implementation of our plants. Today we use only technologies and facilities of our own design, thus becoming an exporter of technology and provider of global plant solutions both as a transfer of know-how and as a supply of complete plants.

Goals

Technologies have been developed for environmental protection and pollution control, a field in which the design and technological skills acquired over the years are of basic importance. Therefore, today we can have an extremely rich know-how, the result of our research but also of collaborations with leading European companies that allow us continuous leadership.

In recent years there has also been a great deal of development in the field of air treatment with technical and design solutions that have resulted in devices that are easy to install, simple to maintain and provide for the complete autonomy of the end customer in their management.cco, the result of our research but also of collaborations with leading European companies that allow us continuous leadership.

Goals

Terminter’s goal is to preserve the distinctive characteristics of its products: good quality, safety, compliance with relevant laws, continuous research and new technical and plant engineering projects. This is done by using external collaborations with European and global certifying bodies to substantiate and approve the adequacy of what is produced. These entities are defined as “Notified,” meaning authorized by the state and “notified” to the authorities of the states of the European Union.

Technological innovation

Terminter: Innovation 5.0

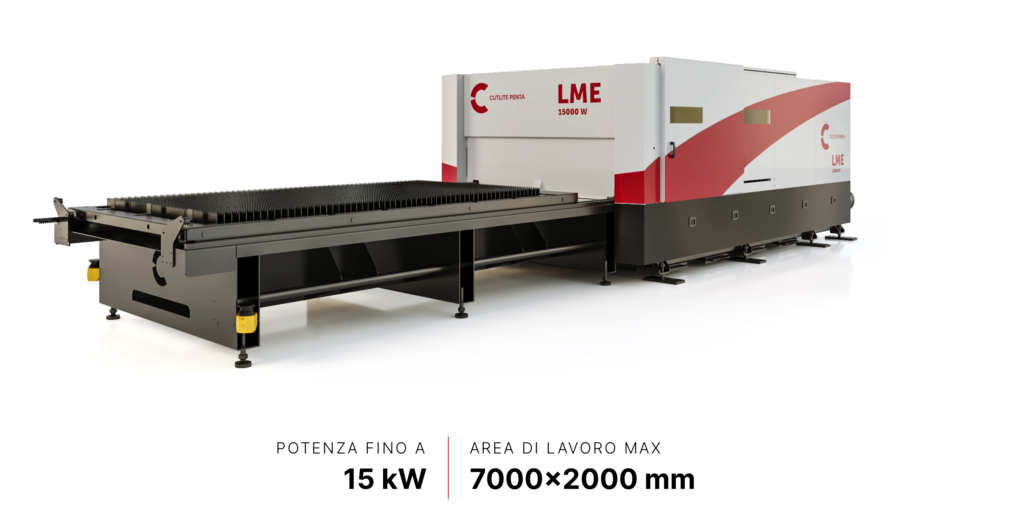

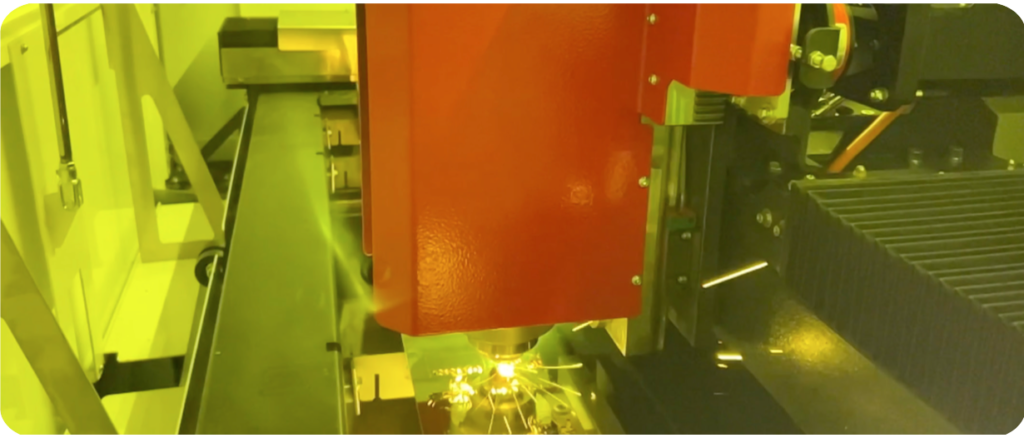

FIBER LASER MACHINE

Ability to produce at very high quality levels with high productivity and low operating costs. Quality of material handling is ensured by the best linear motors available on the market, which together with the Fiber laser source allow high dimensional accuracy in cutting both carbon steel and INOX steel.

Simplicity, and optical path stability converge toward highly optimized, repeatable and reliable results.

The fluid dynamics of the designed cutting head allows for high-pressure cutting with significant econimic production savings. All this makes the system adopted by Terminter one of the most efficient and most reliable available on the Market.

The supplied cutting head has a capacitive sensor that uses the autofocus cutting head entirely designed and manufactured with high-precision mechanics, is equipped with contact and temperature sensors.

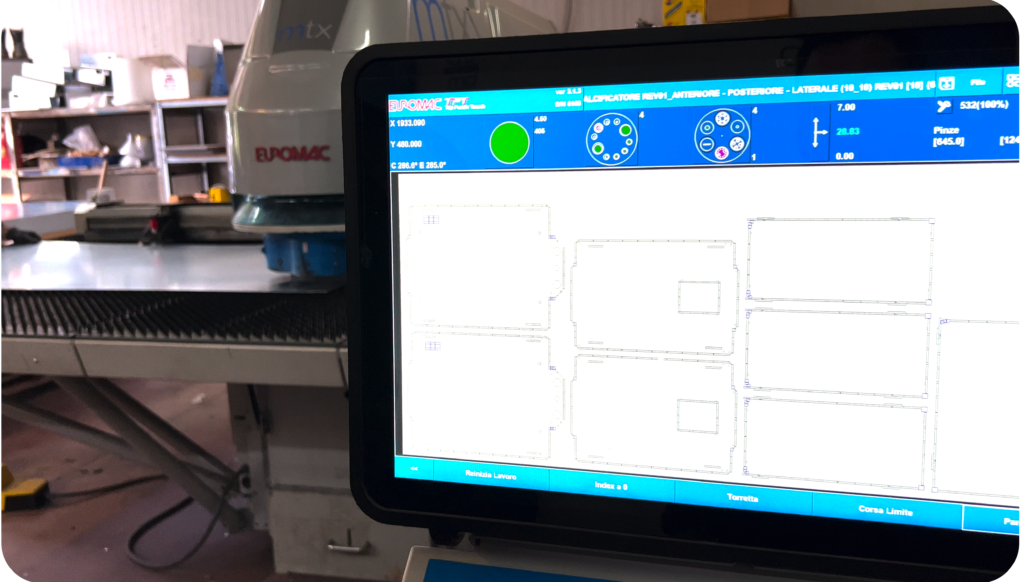

PUNCHING MACHINE: SHEET METAL CUTTING

Another system that works simultaneously with the 4.0 laser system is the new EUROMAC with an increase in the size of the structure that allows it to operate with greater stability and precision of work.ica-such as ammonia, organic matter, algae, cyanobacteria and cyanotoxins-or anthropogenic, due to wastewater, agricultural and industrial activities.

It is capable of punching at high speeds while maintaining a constant punching depth. Great flexibility also to the turret configuration, with 60 or 66 tools.

CNC PRESS BRAKE: 3 AXIS

Stronger, faster and deeper curves;

Hydraulic press brakes allow you to increase production capacity and avoid loss of time during production.

CNC NUMERICAL CONTROL MACHINE: 5 AXIS

The five-axis machining center adopts the layout with the integrated table, capable of controlling all operations of the lathes that read the set parameters and guide the movement of the machine tool on specific axes. The results that can be pursued through CNC turning thus become increasingly varied and precise. Basic rotation that includes the B axes with rotation -30° + 110° and C 360°, and the mast that moves longitudinally (axis Y) on the structure, transversely (axis X) via the RAM sliding in the cradle, and vertically (Z axis) via the vertical ram.

RELIABLE PROFESSIONAL 3D PRINTERS

Rapid or functional prototypes, jigs and fixtures for the production process: Ultimaker 3D printers are ideal for a wide range of applications, with high quality.

SOFTWARE

From CAD design to 3D model in just a few

and simple steps. Ideal for any business or professional, Cura software allows you to manage printing processes remotely as well.

PERFECT PRINTS

The range of filaments are ideal to fully meet any need. Materials, allow for PROTOTYPES with superior performance.

PCB LAB: QUALITY AND ENGINEERING

Our team of quality experts has extensive knowledge of the fabrication of printed circuit boards and technical parts, which enables them to make rapid improvements to your designs. Our quality teams perform monthly monitoring and audits to continuously check the quality performance of our supplier partners.

The engineering department aims to bring true service expertise through improvements in design, technology, materials and processes according to the characteristics and specifics of the customer’s request.